In the United Kingdom, if you want to place a product on the market you need to ensure that you have a CE mark, this is fundamentally the same as the now deprecated UKCA mark. The CE mark will allow you to sell in Europe.

Please see this post about the depreciation of the UKCA mark.

How to get your CE mark

For a lot of electrical devices, there is no requirement to use a notified body, and you can self-certify your device as in compliance with the relevant requirements.

This however doesn’t mean that you can just sign a DoC (Declaration of Conformity) and hope for the best, you will need to ensure that you have the paperwork in place to back up this assertion.

What do I need to do?

Several things need to be done. Looking through the list, we have CE1, RoHS2, WEEE3, and LVD4.

So what do these mean for someone who has just made an electrical device?

If you need EMC work done on your product you should talk to the team at CASS Industries, or Unit 3 compliance who will be able to help you!

RoHS 2

Restriction of Hazardous Substances5 – Directive 2011/65/EU 6 can be done as a paperwork test, Farnell and other suppliers offer to let you search only by RoHS compliant components, so use only these, lead-free PCBs, and lead-free solder, and unless you overlook something simple you won’t go wrong.

It is ok to use Lead solder and HASL PCBs for internal prototyping, but for production, you must work under RoHS 2.

WEEE

Waste Electrical and Electronic Equipment Directive – 2012/19/EU 7 sets out that “Users of electrical and electronic equipment from private households should have the possibility of returning WEEE at least free of charge”, the easiest way to implement compliance is to write in the attached documentation something like: “The device shall be returned to {company name} for disposal”; (and you will cover the P&P of this!) however it is unlikely that you will ever get any returns, however, that is not your issue… You can then place the logo with the black line on your instructions or rating plate (the WEEE logo for items placed on the market between 2002 and 2005 has no black bar after 2005 does).

A better way of managing this is to engage with a company such as Waste Pack which will talk you through compliance with the regulations.

LVD

Low Voltage Directive – 2014 /35/EU8. In the United Kingdom, the LV directive is implemented by “The Electrical Equipment (Safety) Regulations 1994” (a read of BS EN 60335-1:2012 will give you most of what you need to know) however! Battery power is your friend (A supply voltage of above 75 V DC or 50 V AC requires LVD).

Or buy pre-certified wall warts, and when I say pre-certified I don’t just mean from China unless you can tell me what is wrong with this certificate:

See if you can tell what is wrong with this typical certificate you will get for anything bought from China, tell me why it is not valid for a wall wart (hint it is not for a wall wart).

UKCA/CE for EMC

CE marking is a mandatory conformity marking for certain products sold within the European Economic Area (EEA) since 1985.

And since Brexit, there is also the addition of the UKCA mark.

There are a large number of other mandatory conformity markings for other market areas, FCC for the USA (Note that the FCC mark bears no legal status where the CE mark does, and vice versa).

The EMC (Electromagnetic Compatibility Regulations) regulations are intended to allow electronic devices to operate in the same vicinity without causing interference to one another.

An excerpt below from the Electromagnetic Compatibility Regulations 2006, Regulation 4 paragraph 2 states:

Equipment shall be designed and manufactured, having regard to the state of the art, so as to ensure that the electromagnetic disturbance it generates does not exceed a level above which radio and telecommunications equipment or other equipment cannot operate as intended; and it has a level of immunity to the electromagnetic disturbance to be expected in its intended use which allows it to operate without unacceptable degradation of its intended use.

There are fundamentally two parts to electromagnetic compatibility.

- The electromagnetic disturbance, or emissions generated by a piece of equipment.

- The ability of a piece of equipment to withstand electromagnetic noise whilst still functioning as intended.

Any piece of equipment, or product, that is “placed upon the market” must meet the basic tenets of the EMC regulations.

A product, failing to meet the EMC requirements would not only be a breach of the regulations but could conceivably place both the operator and the general public at risk.

The EMC Directive (2004/108/EC) essentially states that before any product is sold in the EU, the supplier (who may be the manufacturer or the importer) must ensure that it will not cause interference (emissions) and that it will operate satisfactorily in its intended environment (immunity).

Test techniques to check the various aspects of emissions and immunity are specified in the EMC Standards. These are the compliance tests. These standards include details of the maximum allowable levels of emissions and the immunity ‘stress’ levels that must be applied.

Electromagnetic emissions produced by a product above prescribed limits could interfere with any of the following items:

- Radio and television receivers

- Information technology networks (eg. WiFi, Internet connections)

- Home automation systems

- Computer-based equipment

- Emergency call systems

- Medical equipment

- Emergency services and enforcement agency communications

The list is representative only. It is not exhaustive and could include many other items.

Inadequate electromagnetic immunity of a product could cause the product to malfunction. The severity of the consequences of failure will vary, depending upon product type and purpose. In the most serious cases, equipment malfunction could cause physical injury, loss of limbs, lacerations, blindness, burns, poisoning, suffocation, or cardiac arrest. In addition, equipment malfunction could cause property damage.

If you can argue that it’s attended equipment. Non-medical. Non-critical and won’t have any degradation of performance under the immunity requirements of BS EN 61000-6-1 you should be fine…

As such you should still look at having emissions testing done, you can sidestep the requirement for Conducted emissions if you don’t use mains power, and don’t supply a charger (a standard USB cable without a charger does not require a conducted emissions test).

This leaves us with the only test you should perform. BS EN 61000-6-3 Table 1 (the levels are the same for FCC CEI 61000-6-3 and IEC 61000-6-3)

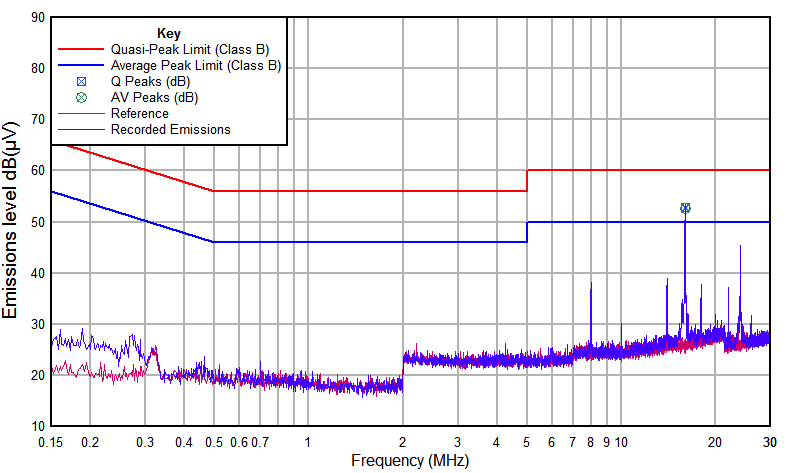

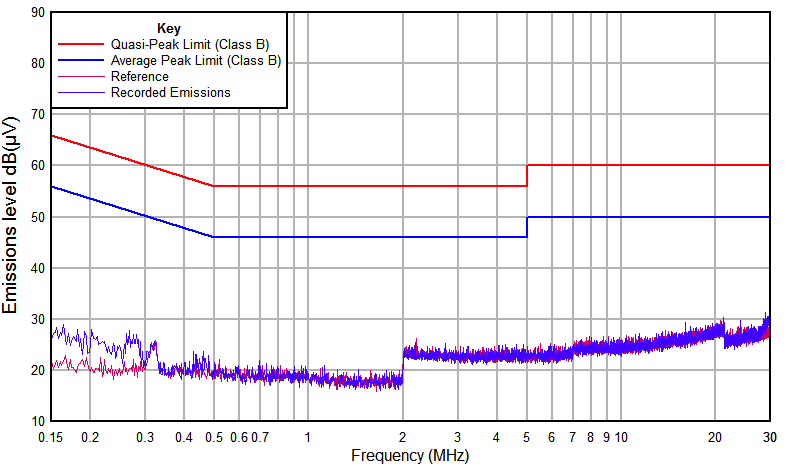

Before you say to yourself how can you design something that doesn’t work, tell me what the difference is between these two graphs, other than one is a pass, and the other is a fail:

The difference is a 100 nF capacitor between Vcc and GND on the Pic μC

LiPol Batteries

I would recommend using a known good LiPol charging circuit and components to manage the charging and discharging of LiPol batteries,

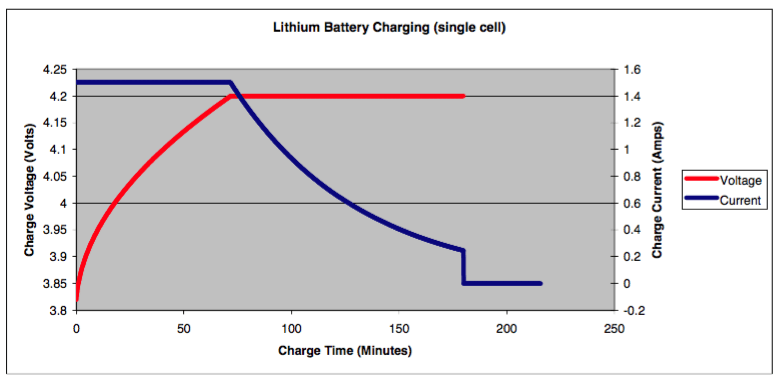

Method of Charging

Set an output voltage of 4.2V on a voltage supply and adjust the current limit to 1.5A maximum output current.

Take care to observe the correct polarity, apply the supply voltage to the battery and monitor the current.

At first, the supply will operate in “constant current mode”, drawing the maximum available current from the supply. The voltage will initially read lower than the original voltage setting but will rise over time as the battery charges.

A point will be reached in the charging cycle where the battery voltage reaches the charging set voltage of the power supply. At this point, the charging current will start to fall and the battery voltage will remain constant. This charging mode is referred to as “constant voltage mode”.

Once constant voltage mode has been achieved, the current decay is closely monitored. When the current falls to a chosen value, typically between 0.02C and 0.1C, then the battery is deemed to be fully charged and the supply voltage must be removed.

If the battery has not achieved a fully charged condition after three hours of continuous charging, then the charge cycle shall be terminated and the voltage supply removed.

Warnings

The voltage applied to a Lithium cell must never exceed the absolute maximum of 4.25V at any time.

A lithium cell should not be allowed to continuously charge, or trickle charge as this is detrimental to the cell chemistry. Once a full charge has been achieved, the applied charging voltage should be completely disconnected to remove the voltage stress placed upon the cells.

Lithium cells should never be discharged below 2.7V and should contain protective circuits to prevent that condition.

Charging lithium cells at a value of current greater than 1C is not generally recommended, although some chemical variants are more tolerant than others.

The charging circuit should not re-engage before the overall cell charge has dropped by at least 5% to 10% from the maximum. This would be manifested as a drop in voltage from the absolute maximum of 4.25V to around 4.0V to 4.1V.

RED

If you use a radio module I in your product, this will bring in the requirement for RED9 and LVD again, I very much recommend using a Pre-Approved module, and it is even better if you use one with a built-in antenna.

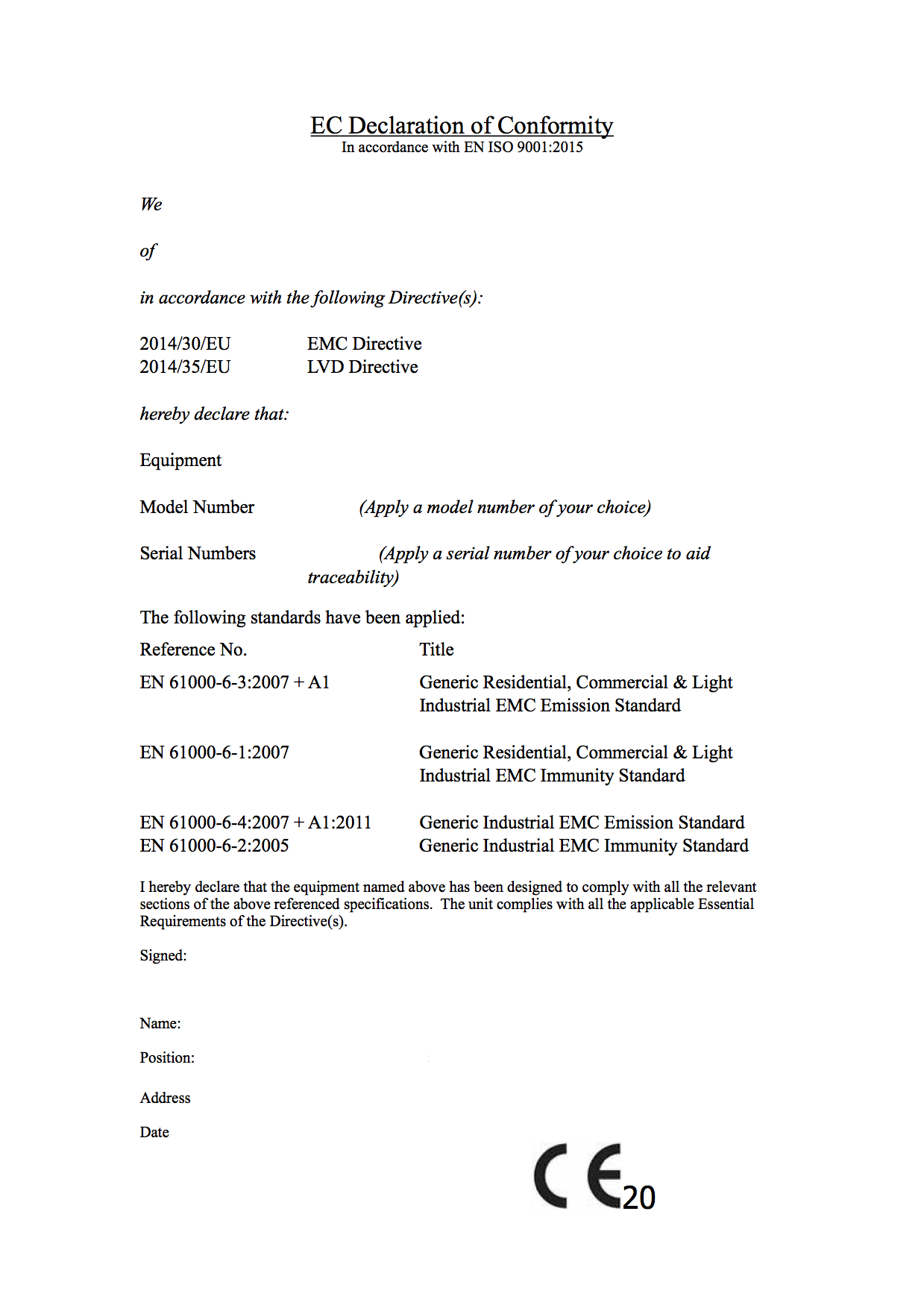

Paperwork

All of these tests bring in paperwork requirements,

Labelling:

- A product label showing a Manufacturer’s name/trademark and address is required.

- A product label showing an Importers name/trademark and address is required.

- A product label showing a type, batch or serial number is required, this should also appear on the DoC (Declaration of Conformity) to aid traceability.

- An importer or distributor is considered to be a manufacturer if they place the equipment on the market in their name or modify the equipment in such a way that compliance with the Directive may be affected.

- Documentation

Instructions for use shall be provided with the equipment.

Technical Documentation must be held (and be available for examination) by the manufacturer, an authorised representative or an importer, to include:

- A general description of the apparatus.

- Conceptual design and manufacturing drawings and schematics of components, sub-assemblies, circuits, etc.

- A list of the harmonised standards applied in full or in part the references of which have been published in the Official Journal of the European Union, and, where those harmonised standards have not been applied, descriptions of the solutions adopted to meet the essential requirements of the Directive. In the event of partly applied harmonised standards, the technical documentation shall specify the parts which have been applied.

- Results of design calculations made, examinations carried out, etc.

- Test Reports.

- The electromagnetic compatibility assessment.

A DoC must be raised by the manufacturer or an Authorised Representative (who has a formal written mandate from the manufacturer to do so).

The DoC must include information to allow easy identification of the product (batch number or photograph etc.)

The Technical construction file must be kept 10 years from the date of placing the item on the market.

Compliance to more than one directive should be shown on a single DoC with references to the appropriate Directives and Standards, however, a DoC should not be made to more than one Directive if they cover the same areas (e.g. EMC and RED or LVD and RED).

- CE marking is a mandatory conformity marking for certain products sold within the European Economic Area (EEA) since 1985. The CE marking is also found on products sold outside the EEA that are manufactured in, or designed to be sold in, the EEA.

- RoHS is a set of EU regulations that implements EU Directive 2002/95 that restricts the use of hazardous substances in electrical and electronic equipment. This directive bans placing on the EU market, any product having an electrical/electronic component containing more than thresholds set for lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants.

- The Waste Electrical and Electronic Equipment Directive (WEEE Directive) is the European Community directive 2012/19/EU on waste electrical and electronic equipment which, together with the RoHS Directive 2002/95/EC, became European Law in February 2003.

- Low Voltage Directive

- While not a CE marking directive, however, you still need to comply with it

- (repeals RoHS 1 2002/95/EC and 2008/35/EC

- (repeals 2002/95/EC)

- (replaced 2006/95/EC in April 2016)

- Radio Equipment Directive

21 thoughts on “Placing a Product on the market – CE Mark”

Aah great yet another regulation mark. Perfect for companies that want to sell goods around the world.

And for every product spend yet another few 1000 bucks to get the mark.

So CE is not good enough anymore for the UK?

Meaning that a lot of manufacturers outside the UK will stop shipping to the UK as they are not going to spend yet another couple of grand into there product without knowing how many they will sell…

Well then:

CE

FCC

UKCA ( better pronounced as F uk A )

Afternoon Daniel, if you had read the entire article, you would have seen that it is a harmonised standard against the CE mark and that you can self-certify the same as you can with the CE mark.

The UKCA mark, and the CE mark should not cost you any additional if you don’t require a notified body to perform the testing on your product. If your product does require a notified body, then they should be able to produce the paperwork for both marks at the same time.

Thanks, I’m wondering about the practicalities of selling a few assembled bits. They won’t be “consumer products” but very much niche hobbyist things yet I still want them to be above board for UK sales.

If you can sell them as prototype boards, that are self-assembly, you don’t need to worry about any of this.

However the closer you move towards selling a product the harder it becomes to get round that.

Very good write-up! Tackles the legal aspects of engineering and product quality.

Thank you 🙂

really helpful ty for sharing!

You’re welcome, This all comes from my years of industry experience. I hope that it will be usefull.

Thanks for this. Great idea and I will update for US centric requirements for my engineering students. Liked your comment that you don’t need a patent but I would make this more prominent.

This post, like all articles on my site, is released under a Creative Commons BY-NC-SA licence.

Looks good, 1 point though, if you place a product on the market in the UK, you need to ensure it’s UKCA marked too.

UKCA and CE are aligned, however, yes in the UK you will need UKCA; I have made the changes above to cover this.

The UKNI mark is one that I am slightly unsure of.

The whole testing system is a farce and killed small industry. I had a small engineering business that was killed of due to all the expenses that, in reality, didn’t improve anything. Electrical safety is one thing, however, some countries such as China produce really unsafe items. CE means China export in China. Take the ESP. The chips have all the certs, however, you still have to spend another 12k just to put the device on the market. I want to make small runs of maybe 100 units. The expense just adds to the cost.

It should not cost anywhere near as much as £12k to put a device through testing; I would look to talk to Dave (CassIndustries.com) or James (unit3compliance.co.uk) to see what a much more reasonable price is.

I am in Australia. UK and US wouldn’t help. Thanks anyway.

I would look at the requirements for the RCM (Regulatory Compliance Mark) – https://www.acma.gov.au/know-what-you-must-do

Best price so far is AU6000. I wonder if a product is put out as an assembled kit, it seems you don’t need RCM or other testing. The same goes for battery operated devices, so long as charging is not built in, or, you remove the battery to charge them.

The biggest road block I’ve faced are patents. Who has $20,000 to throw at a patent for a product that could just flop? And if you can eat that kind of cost it seems like it would be better and safer to invest in mutual funds or something with proven ROI.

You don’t need a patent.

To sell a novel idea, you need a patent, and Johnathan is right – it cost a fortune and one has to ask oneself, why am I spending all this money on a lawyer and perhaps going into debt.

These were my thoughts on a novel hardware phone app years ago.

Agreed. The funny thing is patents were originally intended to be for the garage inventor. They were supposed to protect the little guy. But they are so incredibly expensive that realistically only companies can afford patents.

Patents today are corporate driven. Although I think we are gradually moving away from patents. Software doesn’t necessarily need a patent as long as the IP is secured properly. Perhaps a git repository could be substituted for a patent. Or we just need to have massive penalties for companies that use predatory patenting practices.