The IPC 2221 voltage and spacing standards have two general voltage levels for creepage and clearance, which it defines as “Low Voltage” and “High Voltage”, Some of the “High Voltage” would be considered SELV (Safety Extra Low Voltage), the IPC 2221 Low Voltage is <15 V DC or AC RMS, with everything above that being defined as High Voltage.

IPC 2221 is a functional requirement, not a safety requirement.

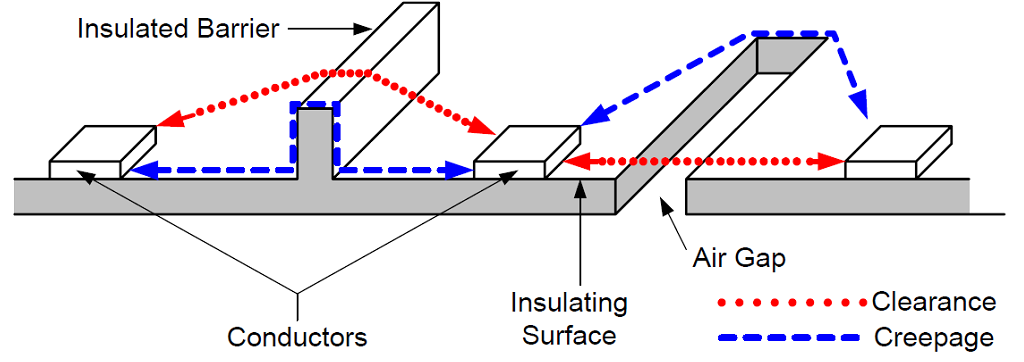

What are Creepage and Clearance?

Creepage is the shortest distance between two conducting points or between a conductive part and the bounding surface of the equipment along the surface of an insulating material. At the same time, clearance is the shortest distance in the air between two conducting parts or between a conductive part and the bounding surface of the equipment.

IPC 2221 is concerned with PCB design, so mostly focuses on creepage from a functional requirement.

Insulation Categories:

There are five categories of insulation used by the different classes of equipment; functional, basic, supplementary, double and reinforced:

- Functional insulation – a basic level that is required for the supply to function. This does not prevent electric shock if touched.

- Basic insulation – provides the user with a single and simple protection from electric shock.

- Supplementary insulation – like basic insulation, must withstand 1.5KVAC (2.1KVDC).

- Double insulation – using basic and supplementary isolation in conjunction to provide redundancy. If the basic fails, the supplementary still protects the user.

- Reinforced insulation – a single layer that performs in the same way as double insulation

IPC-2221 Low Voltage

Under the IPC 2221 voltage and spacing standards, the minimum PCB clearance rule (the clearance between any two conductors) is 0.1 mm for general-purpose devices. There is a table below showing different requirements for different physical environments.

At these voltages, most of the tracks will be digital signals, low-frequency analogue signals, or DC supplies at low currents, You’re still well within IPC 2221 requirements with these traces, and your primary focus should be efficient routing and DFM.

| Current (1 oz CU) | External trace width (mm) |

|---|---|

| 400 mA | 0.085 (Round up to 0.1 mm). This is the smallest physical size recommended. |

| 500 mA | 0.115 |

| 600 mA | 0.145 |

| 700 mA | 0.184 |

| 800 mA | 0.221 |

| 900 mA | 0.260 |

| 1000 mA | 0.300 |

The above Current ratings are indicative only and calculated for 400 mA to 1000 mA, on a 1 oz CU copper external layer only. for further details on IPC-2221 track widths, There is the post “IPC 2221 standard trace widths” that will give further details.

| The voltage between Conductors (DC or AC peaks) | Minimum Spacing | ||||||

|---|---|---|---|---|---|---|---|

| Bare Board | Assembly | ||||||

| B1 Internal conductors | B2 External conductors uncoated, sea level to 3050 m | B3 External conductors uncoated over 3050 m | B4 External conductors with a permanent polymer coating | A5 External conductors with a conformal coating over the assembly | A6 External component lead/termination, uncoated, sea level to 3050 m | A7 External component lead/termination with a conformal coating. | |

| 0 – 15 V | 0.05 mm | 0.1 mm | 0.1 mm | 0.05 mm | 0.13 mm | 0.13 mm | 0.13 mm |

IPC-2221 High Voltage

At “high DC voltage”, the primary concern in choosing a PCB trace clearance value is preventing ESD and dendritic growth between exposed conductors. With high AC voltage, or with a switching regulator that outputs high current, you now have to worry about crosstalk, as well as ESD and dendritic growth.

Dendritic growth is a rare electrochemical phenomenon that can occur on PCBs in the presence of contamination, high humidity and voltages, this is where metal physically migrates causing short circuits.

Crosstalk suppression guidelines still over-specify the required PCB voltage clearance or spacing between conductors until you get to very high voltages.

The following table is for Functional separation as IPC-2221 is not a safety standard, If you are not using SELV voltages you will need to take that into account.

| The voltage between Conductors (DC or AC peaks) | Minimum Spacing (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Bare Board | Assembly | ||||||

| B1 | B2 | B3 | B4 | A5 | A6 | A7 | |

| 0 – 15 | 0.05 | 0.1 | 0.1 | 0.05 | 0.13 | 0.13 | 0.13 |

| 16 – 30 | 0.05 | 0.1 | 0.1 | 0.05 | 0.13 | 0.25 | 0.13 |

| 31 – 50 | 0.1 | 0.6 | 0.6 | 0.13 | 0.13 | 0.4 | 0.13 |

| 51 – 100 | 0.1 | 0.6 | 1.5 | 0.13 | 0.13 | 0.5 | 0.13 |

| 101 – 150 | 0.2 | 0.6 | 3.2 | 0.4 | 0.4 | 0.8 | 0.4 |

| 151 – 170 | 0.2 | 1.25 | 3.2 | 0.4 | 0.4 | 0.8 | 0.4 |

| 171 – 250 | 0.2 | 1.25 | 6.4 | 0.4 | 0.4 | 0.8 | 0.4 |

| 251 – 300 | 0.2 | 2.5 | 12.5 | 0.4 | 0.4 | 0.8 | 0.8 |

| 301 – 500 | 0.25 | 2.5 | 12.5 | 0.8 | 0.8 | 1.5 | 0.8 |

| > 500 | V x 0.0025 | V x 0.005 | V x 0.025 | V x 0.00305 | V x 0.00305 | V x 0.00305 | V x 0.00305 |

Safety Extra Low Voltage

IEC defines a SELV system as “an electrical system in which the voltage cannot exceed ELV under normal conditions, and under single-fault conditions, including earth faults in other circuits”. It is generally accepted that the acronym: SELV stands for separated extra-low voltage (separated from the earth) as defined in installation standards, though BS EN 60335 refers to it as safety extra-low voltage.

| Meaning | Voltage limit | Can be accessible | |

|---|---|---|---|

| ELV | Extra Low Voltage | < 50 VAC / 125 VDC | yes |

| SELV | Safety / Separated Extra Low Voltage | < 42 VAC / 120 VDC (no load) | yes |

| LV | Low Voltage | 50 – 1000 VAC / 125 – 1500 VDC | no |

Safety Creepage and Clearance

The generic base standard in the UK for “Household and similar electrical appliances” from an electrical safety standpoint is BS EN 60335-1 (IEC 60335-1),

Clearance

Clearance is covered in clause 29, using tables 15 and 16.

| Rated Voltage (V) | Rated impulse voltage (V) Overvoltage category | ||

|---|---|---|---|

| I | II | III | |

| <50 | 330 | 500 | 800 |

| >50 and <150 | 800 | 1500 | 2500 |

| >150 and <300 | 1500 | 2500 | 4000 |

| Note 1: For multi-phase appliances, the line-to-neutral or line-to-earth voltage is used for rated voltage. Note 2: The values are based on the assumption that the appliance will not generate higher overvoltages than those specified. If higher overvoltages are generated the clearances have to be increased accordingly. | |||

| Rated Impulse voltage (V) | Minimum clearance (mm) (See note a) |

|---|---|

| 330 | 0.5 (see notes b, c and d) |

| 500 | 0.5 (see notes b, c and d) |

| 800 | 0.5 (see notes b, c and d) |

| 1500 | 0.5 (see note c) |

| 2500 | 1.5 |

| 4000 | 3.0 |

| 6000 | 5.5 |

| 8000 | 8.0 |

| 10000 | 11.0 |

| Note a: The distance specified apply only to clearance in the air. Note b: The smaller clearance specified in IEC 60664-1 has not been adopted for practical reasons, such as mass production tolerances. Note c: This value is increased to 0.8 mm for pollution degree 3 Note d: For tracks of [PCB] printed circuit boards this value is reduced to 0.2 mm for pollution degree 1 and pollution degree 2. | |

Creepage

Creepage is also covered in Clause 29, using table 17. however, the maths is made more complicated by having to take into account pollution degrees and material Comparative Tracking Index (CTI) values, CTI values can be found in IEC 60664-1.

The better the insulation, the higher the CTI (positive relationship). In terms of clearance, a higher CTI (measured in volts) value means a lower minimum creepage distance required, and the closer two conductive parts can be.

- Material group I: 600 V < CIT

- Material group II: 400 V < CTI < 600 V

- Material group IIIa: 175 V < CTI < 400 V

- Material group IIIb: 100 V < CTI < 175 V

Standard FR4 (normal PCB material) has a Performance Level Category (PLC) of 2, which puts its CTI as 250 V – 399 V, meaning it is in the material group IIIa, the PLC can be determined for other materials by consulting the datasheet, the use of Solder Mask and Conformal Coating can affect the PLC of the finished board.

Pollution degree

In addition to the CTI, it is required to know the effect of pollution on the insulation, for the purpose of evaluating creepage distances, the following degrees of pollution are defined in IEC 60664-1

- pollution degree 1: no pollution or only dry non-conductive pollution occurs. Pollution has no influence;

- pollution degree 2: only non-conductive pollution occurs, except that occasionally a temporary conductivity caused by condensation is to be expected;

- pollution degree 3: conductive pollution occurs or dry non-conductive pollution occurs that becomes conductive due to condensation that is to be expected;

- pollution degree 4: the pollution generates persistent conductivity caused by conductive dust, rain, or snow.

| Working Voltage (V) | Creepage distance (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Pollution degree | |||||||

| 1 | 2 | 3 | |||||

| Material Group | Material Group | ||||||

| I | II | IIIa / IIIb | I | II | IIIa / IIIb (see note a) | ||

| < 10 | 0.08 | 0.4 | 0.4 | 0.4 | 1.0 | 1 | 1.0 |

| 50 | 0.16 | 0.56 | 0.8 | 1.1 | 1.4 | 1.6 | 1.8 |

| 125 | 0.25 | 0.71 | 1.0 | 1.4 | 1.8 | 2.0 | 2.2 |

| 250 | 0.42 | 1.0 | 1.4 | 2.0 | 2.5 | 2.8 | 3.2 |

| 400 (see note b) | 0.75 | 1.6 | 2.2 | 3.2 | 4.0 | 4.5 | 5.0 |

| 500 | 1.0 | 2.0 | 2.8 | 4.0 | 5.0 | 5.6 | 6.3 |

| >630 – <800 | 1.8 | 3.2 | 4.5 | 6.3 | 8.0 | 9.0 | 10 |

| >800 – <1000 | 2.4 | 4.0 | 5.6 | 8.0 | 10 | 11 | 12.5 |

| Note 4: For working voltages > 10 V and < 630 V, if the voltage is not specified in the table, the values of creepage distance may be found by interpolation. | |||||||

| Note a: Material group IIIb is allowed if the working voltage does not exceed 50 V. Note b: The working voltage between phases for appliances having a rated voltage in the range of 380 V to 415 V is considered to be 400 V. | |||||||

Rule of Thumb for 230 V

Assuming a hazardous voltage of 230 VAC single-phase mains, the following table shows nominal creepage and clearance distances:

| Clearance | Creepage | Distance through Insulation | Stress Voltage | |

|---|---|---|---|---|

| Basic Insulation | 2.0 mm | 2.5 mm | not specified | 1.5 kV AC (2.1 kV DC) |

| Double or Reinforced Insulation | 4.0 mm | 5.0 mm | 0.4 mm | 3.0 kV AC (4.2 kV DC) |

Summery

Most of the time you will be in pollution degree 1, so it doesn’t really matter about the choice of the material group, however, there are outliers.

In the next post, I will write up the summary of these two pages, with what I have as a set of rules for use in KiCad