Around the world, there are a variety of different EV charging connector types used on Battery electronic vehicles (BEV) and Plug-in Hybrid Electric Vehicles (PHEV). The use of EV Connectors tends to be split into geographical regions, with different connectors being concentrated in each geographical region.

EV charging connector types used in the European Union and United Kingdom

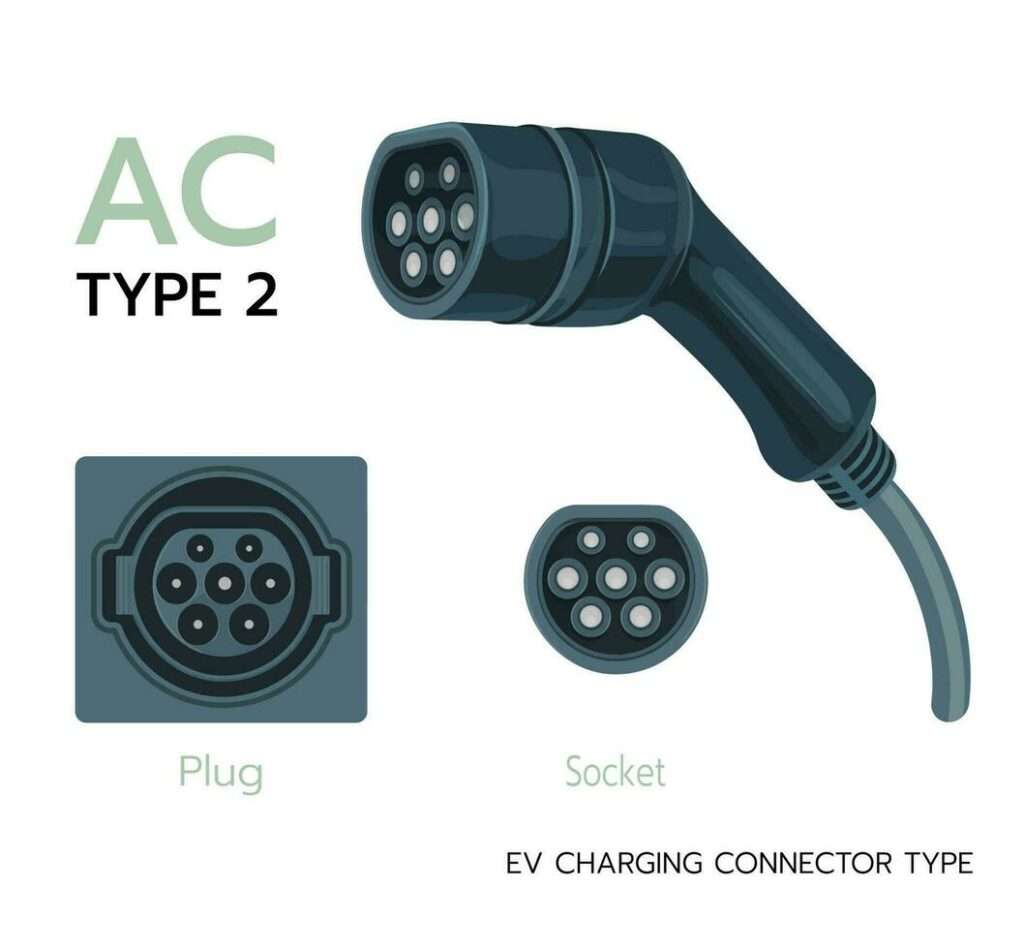

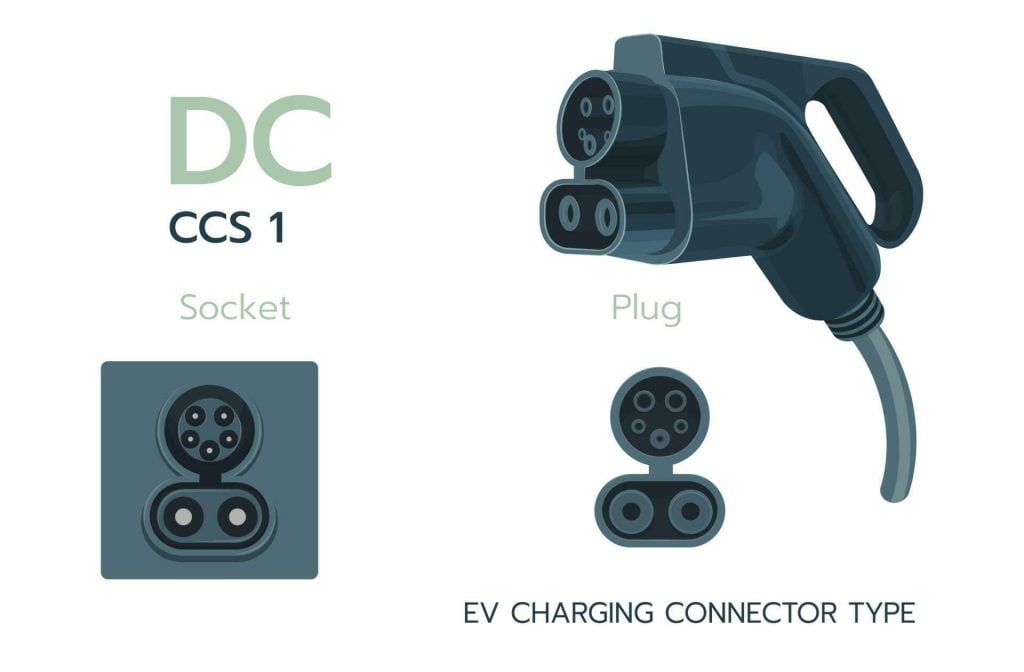

Most BEVs and PHEVs in the UK and EU (Including Tesla) excluding a limited number of vehicles use IEC 62196 Type 2 (sometimes referred to as Mennekes) and Type 2 Combined Charging System (CCS) connectors (Older Nissan Leafs use Type 1 connector for AC charging, and all current Nissan Leafs use CHAdeMO for DC). There may be other examples of these exceptions, but I am not personally aware of them at the moment other than Mitsubishi.

This use of Type 2 and Type 2 CCS is harmonisation in the EU and UK and is part of the work performed by the EU’s Sustainable Transport Forum. It is mostly encoded in EU directive number 2019/94/EU known as the “Alternative Fuels Infrastructure Directive” (AFID).

The Type 2 AC connector primarily uses CP/PP (Command Pilot / Proximity Pilot) as its communication between the Electric Vehicle Supply Equipment (EVSE) and the BEV / PHEV. However, in addition to CP/PP there is provision for Power Line Communication (PLC). The Type 2 connector can be wired to support three-phase AC power as well as single-phase.

The Type 2 has a maximum output of 19.2 kW, with the Type 2 CCS “fast charging” having a maximum rating of up to approximately 350 kW.

In the UK Type 2 and Type 2 CCS Vehicle inlets and other accessories can be bought from this company.

EV plugs and sockets in North America

Until recently the North American market was made up of predominantly Type 1, and Type 1 CCS, with limited usage of Type 2 for specific scenarios. Tesla has a connector for their cars.

Recently the Tesla connector has been accepted by more OEMs and has been rebranded as NACS – North American Charging Standard.

The Type 1 and Tesla connectors are only able to provide single-phase (split) AC. so when three phases are required, vehicles are fitted with Type 2 connectors.

Since most American households are supplied with a split phase, the single phase is 220 VAC (+110 and -110 VAC with respect to Protective Earth) at 60 Hz,

The Tesla / NACS connector is unique in the respect that the two current-carrying conductors are capable of either AC or DC supply, depending on the Vehicle and the EVSE. To support this, The Vehicle will need additional contractors before the OBC (On Board Charger), and additional information in the communications protocol.

Communication between the EVSE and the EV can be either CP/PP or PLC.

Japan’s EV Connectors

The EV Connectors used in Japan tend to be Type 1 and CHAdeMO, which is an abbreviation of “CHArge de MOve” (“charge for moving”) and is derived from the Japanese phrase “o CHA deMO ikaga desuka“, which when translating to English as “How about a cup of tea?”.

First-generation CHAdeMO connectors can deliver up to 62.5 kW (500 VDC 125 A), Second-generation allows for up to 400 kW (1 kV, 400 A). The popularity of CHAdeMO was restricted by the EU’s introduction of the Alternative Fuels Infrastructure Directive (AFID). Unlike Type 1, and Type 2 CHAdeMO has additional data pins for CAN communications.

There is a third generation of CHAdeMO, with the code name ChaoJi. It is designed to support a charging rate of 900 kW (600 A x 1.5 kV), all the while ensuring backward compatibility with the current CHAdeMO and GB/T 20234.3 (IEC 62916-3 configuration BB) DC chargers. However, I don’t know how much implementation it has.

China’s EV Connectors

The Chinese market has its own standards for EV Charging cables and Connectors, the connectors have ended up being known as GB/T.

The GB/T standards are mostly harmonised against ISO, IEC, and SAE standards

- GB/T 18487 – Conducting Charging Systems for Electric Vehicles, corresponding to IEC 61851.

- GB/T 20234 – Connectors for Conducting Charging for Electric Vehicles, corresponding to IEC 62196 and SAE J1772.

- GB/T 27930 – Communication Protocol between Off-board Conductive Charger and Battery Management System of Electric Vehicle, corresponding to ISO 15118 and SAE J1772.

The AC connector is also manufactured by Mennekes, the same as the Type 2 connector, the GB/T 20234.2 AC connector is very similar to the Type 2, but in the other gender. The DC connector is known as GB/T 20234.3

The AC GBT connector uses CP/PP communication while the DC GBT connector uses CAN BUS signalling for control, This is unlike the power line communication (PLC) control protocol used in the competing CCS standard, which originated from the European Type 2 connector and North American SAE J1772 (Type 1) standards for AC charging.

52 thoughts on “Different EV Connectors”

For a type 2 charger for Rav4 prime, I am not sure which wire (pink or orange) is a co and a pp. does the cp connect with earth and pp with live?

I cover the wiring of CP and PP in subsequent posts.

It may be a good time for EV mags to make the OBCs available to owners for use as a home DC charger.

As car battery capacity is doubling with solid state batteries, home DC charging will be needed to fully charge them overnight.

I suspect that this information is all available over the PLC or CAN communications on the DC connector between the EV and EVSE

New Zealand has adopted the EU rules for EV charging. Therefore NZ new Teslas have CCS2 connector on them. Although there are some used import Tesla’s here that have the NACS connector on them.

So more nationalism BS. Great.

How so?

Electrons are the same all over the earth – why do we need different plugs?

I get how it happened over the evolution of electrical distribution, but EVs have “happened” everywhere at the same time so there’s no need for fundamental technical differences. Sure, the world runs on slightly different electrical standards but the same chargers/controllers/metering hardware could/should/will work worldwide.

There are technical differences between the interfaces.

but those technical differences should all be addressing the same sorts of problems. It would be nice to have a single standard for *something*.

AFID solved this in the EU marketplace, it’s called Type 2 and Type 2 CCS. OEMs North America looked at this 2019 directive, and ignored it, and went with an inferior option

you realise there are wild functional differences between the types, required to meet local requirements? 😂

There was a teathered version of the Type 2 capable of delivering 44kW over 3 phases in the UK, however very few cars could make full use of it (the first generation of the Renault Zoe being the only example I know of). However that’s more or less gone now.

I also wanted to show you what your article looks like when i open it:

* huge popup banner

* blocks 20% screen

* oversize font and whitespace

* i have to scroll after reading only 20 words.

* that’s 100 scrolls for a rather short article

* you could save at least 400 words by editing out all propositions and pronouns among other tech writing tricks.

Don’t get me wrong, we need good articles about charger use

I will look into making the article more concise.

Tesla having their own connector, the only single company in the world doing this, should really be something to think about for the US EV users. The fact that it’s now adopted as the main charging standard for the US should make you think a bit harder still. Googling “monopoly” might help.

It’s not a monopoly if they’re not profiting off the connector design.

It’s not a monopoly if they have by far the largest country-wide fast charging network? Normally, you have standards first and then you build networks. Tesla built the network first and pushed through the standard later.

It’s not a monopoly if it’s released to the public domain or similar sharing.

the plug is not the monopoly, it’s a symptom of one, I was hoping that much was clear from my original comment.

I would like to know why they pushed so hard for the acceptance of their connector as the de-facto standard.

because they built out the largest charger network first, and they sure as hell don’t rant to be the ones that have to change their equipment if another standard won the war. That’s a cost to be borne by the also rans.

you just pulled that out of your ass:

CCS was already standardised AND backed by major industry players in mid 2012. NACS was standardised in 2022 and is the adapted proprietary Tesla connector designed in 2012. So it’s just a simple case of avoiding an existing standard to lock in users, like it often happens in tech.

they didn’t. They did however have a superior network and a connector ten times better than the “standard”. The entire American industry couldn’t beat them, so joined them.

how is it “10 times better”? Because you can’t use it with three phase power? Cheerleading looks better on cheerleaders.

The CCS1 connector in the USA can’t use 3 phase power either. Europe uses CCS2.

I know that, but as electrification progresses, 3-phase will become ubiquitous doe to the many advantages it has. Staying locked to a one phase connector will cause trouble down the road.

Anything You use was born like that…

you would think that, but CCS was already standardised AND backed by major industry players in mid 2012. NACS was standardised in 2022 and is the adapted proprietary Tesla connector designed in 2012. So it’s just a simple case of avoiding an existing standard to lock in users, like it often happens in tech.

https://en.wikipedia.org/wiki/Combined_Charging_System

https://en.wikipedia.org/wiki/North_American_Charging_Standard?useskin=vector

This may be the one good thing Telsa has done.

Sure, another thing the USA does differently to most of the rest of the world is a good thing. Getting locked in to a charging standard that doesn’t allow three phases regular charging is an even better thing for sure.

Let’s talk again in 15 years, when the electrification is in full swing and the Tesla charging network becomes as enshittified as Amazon at al are now. Monopolies are good for a year or two, bad for a generation, and then they get broken up. The plug is just a symptom.

as long as it’s available to others and not priced to the gills, that’s just called a standard

yep, it’s a standard and a symptom.

symptom of them building a good standard first.

you just pulled that out of your ass:

CCS was already standardised AND backed by major industry players in mid 2012. NACS was standardised in 2022 and is the adapted proprietary Tesla connector designed in 2012. So it’s just a simple case of avoiding an existing standard to lock in users, like it often happens in tech.

i’ll suggest that tesla was the only major player in 2012, so it doesn’t much matter. how many cars did the rest of the makes ship?

I could understand them in 2012, but not a couple of years later. As an electrical engineer with a masters degree in electronics I can confidently tell you one thing: using proprietary tech where good international standards are available is evil. It’s bad for the environment, users, repair, and free competition. It always turns out to be some kind of a lock-in scheme with Apple being the flagship example.

Gotta love doubling down on a connector that will likely not see wider adoption outside of the US since, it lacks features of something like Mennekes/CCS2 plug.

There’s a type 3 too. Only in France I believe?

The IEC 62196 Type 3 connector (often referred to as Scame for the company that designed it), Historically it was used in France and Italy.

The Type 3 connector comes in two physical formats, Type 3A for single-phase 230V and Type 3C for single- and three-phase 400V power.

Both have since been superseded by the Type 2 connector.

just like back in the day of the usb wars of 2004 to 2007. one will emerge a victor, and then they will still also be sony( or in the case tesla)

im betting on none of these and a new better then all will come to surface soon

At the moment it is looking like Type 2 (and Type 2 CCS) for the majority of the world, Thanks to the EU with AFID. and NACS (ex Tesla) in the North American market.

I havent looked deeply into the specs but they’re gonna need enough surface area on the plugs to handle 300 miles of travel in 15 to 20 mins. thats probably around 100kwh at a rate of 300kw to 400kw.

for the trucks on the 1 ton segment(that dont exsist yet but will) they will probably need closer to 800 to 1200kw charging. based on needing to have 300kwh batteries.

so probably a future evolution of type 2 with its connector size apporite for those charge rates,

batterys gotta catch up first.

Liquid-cooled cables are going to start to need to be added.

Battery technologies are being worked on.

you can always make cables bigger. But room temperature super conductors and right around the corner. I can just feel it. Id guess we run mini hydrogen fusion reactors by 2100 to meet local power demands. 2040 we should achieve the next wave of fusion. They are already positive output!

Water-cooled cables have less copper and are smaller than making the cables bigger. This is turn is cheaper to manufacture, also easier to handle.

Are the J1772 connectors in Japan and North America interchangeable?

Yes the Japan and North American J1772 are the same

just wait until the next gen Chinese connector takes over the world. it’s called LGB/T

There is no need to make the homophobic jokes

Tesla use Type 2 and GB/T in China, not the Tesla connector.

Tesla Charge-ports – 2022

Thanks for that information, that is very useful to know; I will update the article