One of the standard tests for EMC testing is ESD Testing, It is one of the tests worth doing first, so if you fail this test, you haven’t spent all that much time or money on testing.

In most cases, you will be looking at “IEC 61000-4-2: Electromagnetic compatibility (EMC) – Part 4-2: Testing and measurement techniques – Electrostatic discharge immunity test” as the base standard.

This is one of the first tests I would suggest that you become familiar with if you are looking at becoming an EMC Technician or Engineer.

The TESEQ ESD Discharge simulator shown on the right was bought from instruments4engineers when I was building up the EMC facilities at ARRIVAL.

IEC 61000-4-2 – Electromagnetic Compatibility (EMC) – Part 4-2: Testing and measurement techniques – Electrostatic discharge immunity test

This standard lists the methodology, levels and test methods to achieve compliance for an electronic product. Like most standards, the purpose is to create a way to repeat the test either at the same test lab or a different one, ground for product compliance. The standard defines ranges, levels, test equipment, setups, procedures, calibrations, generator waveforms and general uncertainties. The intention is not to define product-specific tests but instead to establish an essential common reference.

Most products will take the test levels as specified in either BS EN IEC 61000-6-1 (Electromagnetic compatibility (EMC) Part 6-1: Generic standards – Immunity standard for residential, commercial and light-industrial environments) or BS EN IEC 61000-6-2 (Electromagnetic compatibility (EMC) Part 6-2: Generic standards – Immunity standard for industrial environments). For products that don’t fit in the generic standards, and have product-specific standards, the test levels are instead defined in standards such as:

- EN 50130-4 – Alarm systems. Electromagnetic compatibility. Product family standard: Immunity requirements for components of fire, intruder, hold-up, CCTV, access control and social alarm systems

- EN 50121-4-2 – Railway applications. Electromagnetic compatibility. Emission and immunity of the signalling and telecommunications apparatus

- IEC 60601-1-2 – Medical electrical equipment. General requirements for basic safety and essential performance. Collateral Standard: Electromagnetic disturbances. Requirements and tests

- ISO 10605 – Road vehicles: Test methods for electrical disturbances from electrostatic discharge

When working for Automotive OEMs I was also using ISO 10605: Test Methods for Electrical Disturbances From Electrostatic Discharge on Automotive Road Vehicles as the base standard (ISO 10605 also has additional test requirements, including Annex F), however, test levels were defined in the OEMs specific standard.

The product, DUT (Device Under Test) or EUT (Equipment Under Test), is seen from an operator’s point of view during the test. Therefore, The EUT is operational, and testing does not include storage or transportation conditions.

IEC 61000-4-2 Test levels

The EUT is subjected to three types of discharge. Direct contact discharge is preferred either directly to the EUT or indirectly through vertical or horizontal coupling planes. Air discharge is used where direct contact cannot be applied.

Most of the standards mentioned above make use of the standard test levels from IEC 61000-4-2 (IEC 61000-4-2 uses a 150 pF / 330 Ω network), the values can be found in Table 1 of the standard.

| Test Level (150 pF 330 Ω) | Contact discharge test voltage | Air discharge test voltage |

|---|---|---|

| 1 | ±2 kV | ±2 kV |

| 2 | ±4 kV | ±4 kV |

| 3 | ±6 kV | ±8 kV |

| 4 | ±8 kV | ±15 kV |

| x (note 1) | Special | Special |

| Notes: 1. “x” can be any level, above, below or in between the others. The level shall be specified in the dedicated equipment specification. If higher voltages than those shown are specified, special test equipment may be needed. | ||

When applying discharges to a DUT it is recommended to apply them starting at the lowest level, and working up to the maximum specified test level. This is due to the way ESD protection could be implemented in the DUT.

| Contact discharge test level | Air discharge test level | |

|---|---|---|

| BS EN IEC 61000-6-1 – Immunity standard for residential, commercial and light-industrial environments) or | ±4 kV | ±8 kV |

| BS EN IEC 61000-6-2 – Immunity standard for industrial environments) | ±4 kV | ±8 kV |

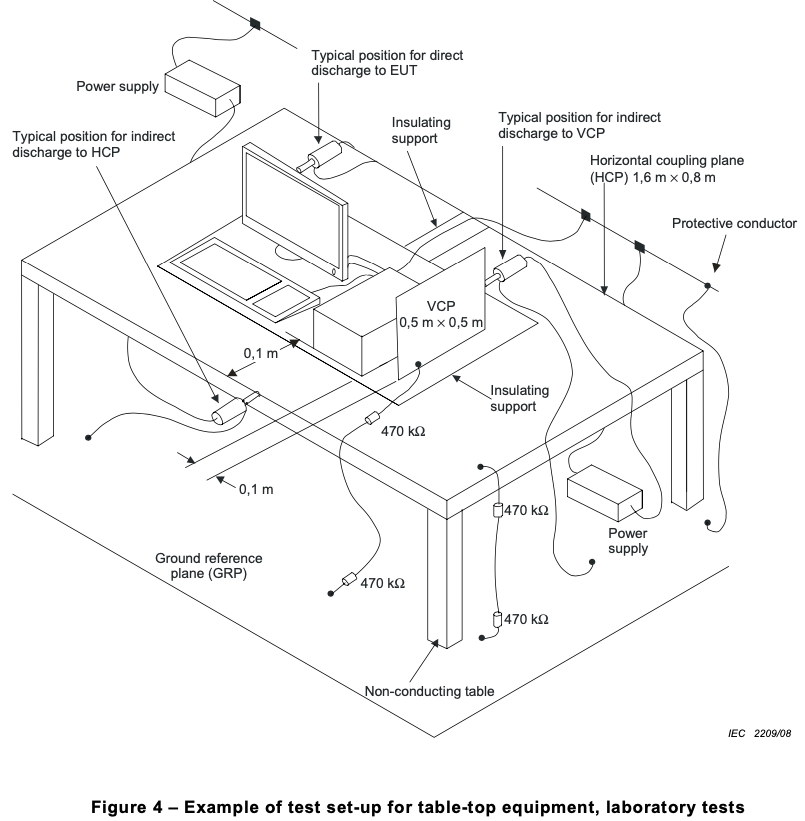

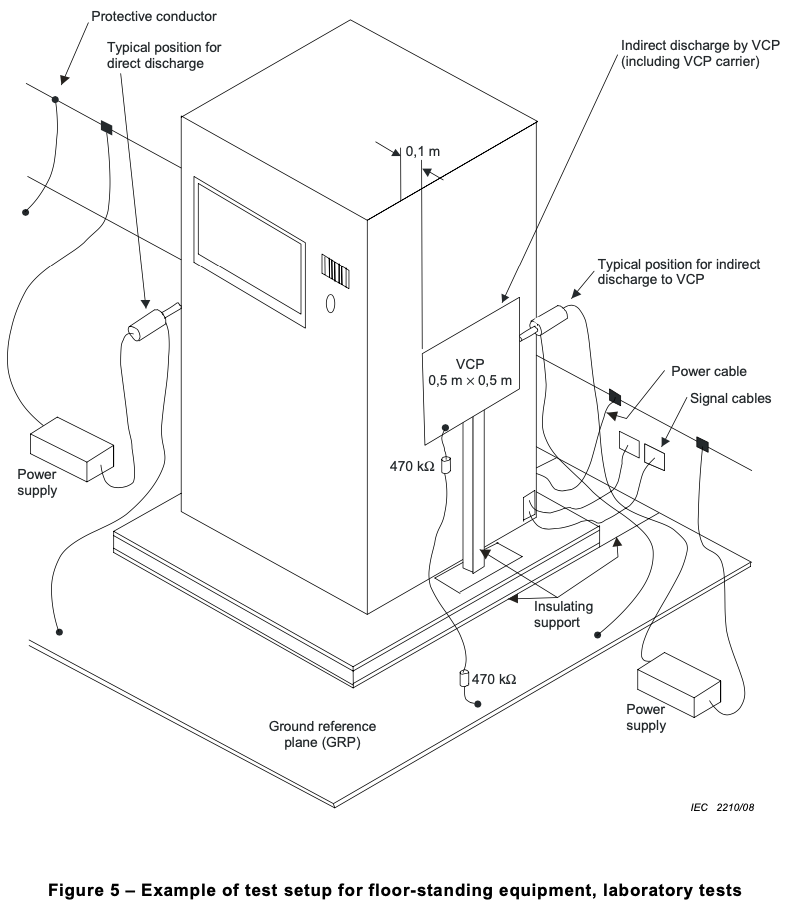

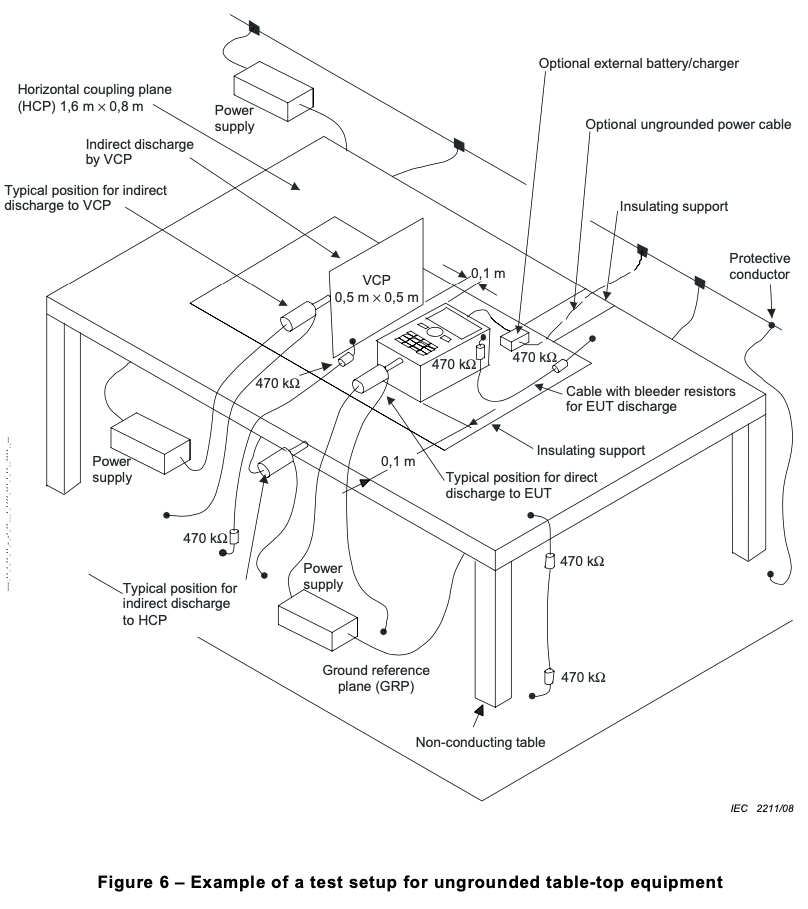

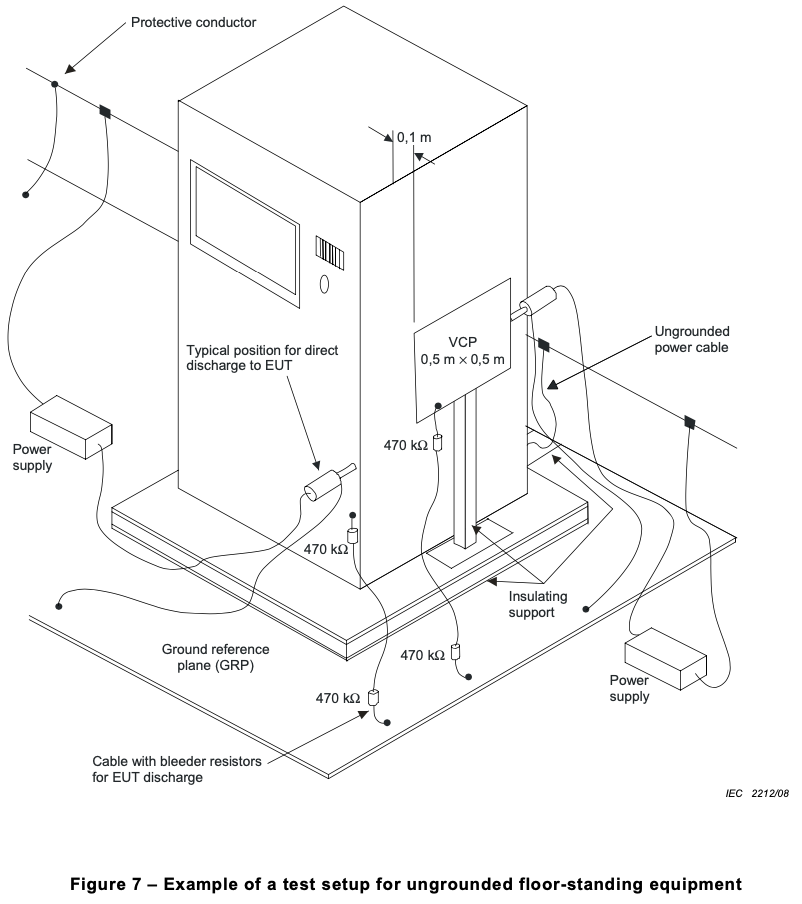

IEC 61000-4-2 ESD Test Setups

Where a table is used in the test setup, the table shall be 0.8 (± 0.08) meters tall made of a non-conductive material and placed on the GRP (ground reference plane). On top of the table an HCP (horizontal coupling plane) shall be placed, its dimensions shall be 1.6 ± (0.02) x 0.8 (± 0.02) meters. The HCP shall be bonded to the GRP via two 470 kΩ bleed resistors on a grounding wire1. The DUT shall be insulated from the HCP by an insulating support with a thickness of 0.5 (± 0.05) mm.

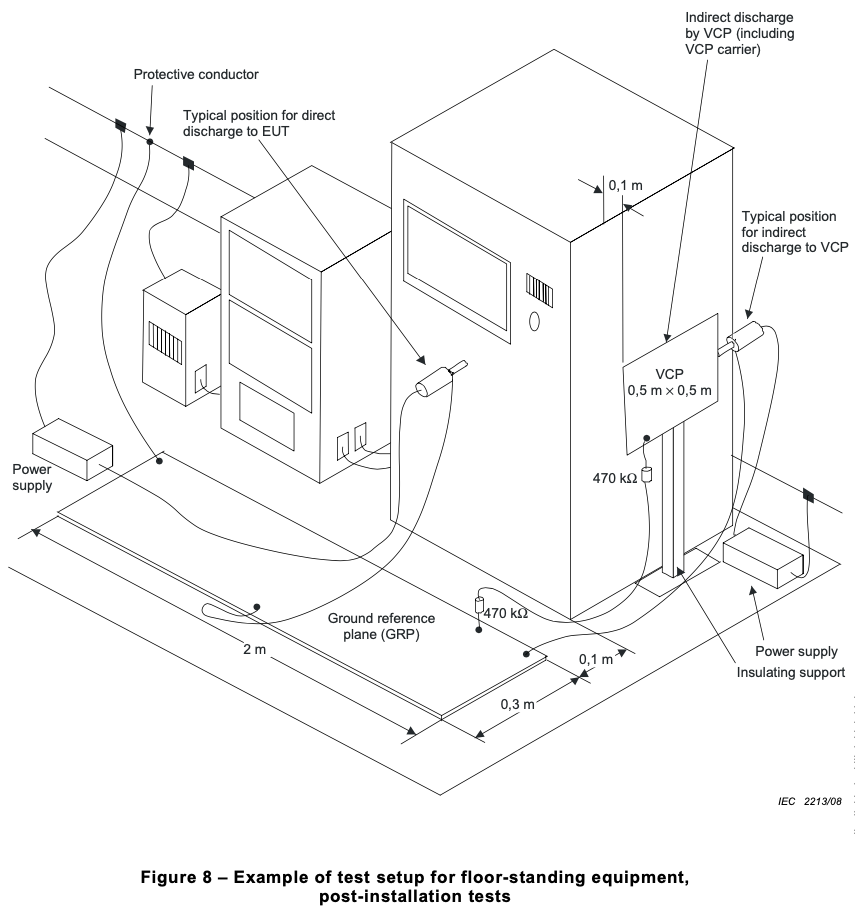

A VCP (Vertical Coupling plane) shall be used to apply discharges 100 mm from the vertical edges of the DUT. the VCP shall be 500 x 500 mm, and connected to the GRP via a grounding cable.

For Laboratory testing of floor-standing equipment, the DUT shall be placed on an insulating support between 50 – 150 mm tall above the GRP, the cables shall be isolated from the GRP using an insulating support with the same properties as the tabletop insulating support.

If the EUT is un-grounded a grounding cable shall be used to ground the enclosure to the GRP between each pulse to remove the applied charge.

Post-installed tests require a little more setup.

ESD Discharge types

Contact discharge tests

Contact discharges are carried out using the sharp point probe (between 25 and 40 degrees), with the simulator applied directly to a conductive part of the DUT, HCP or VCP when the discharge switch is closed.

Air discharge tests

Air discharges are carried out using the rounded tip probe, with the simulator held away from the DUT the discharge switch (trigger) is closed and the probe is taken towards a non-conductive part of the DUT.

Other ESD test setups

This post is getting a little long, but I believe it covers a good background on ESD testing. I will write up ISO 10605 Automotive component testing in a separate post soon.

- The 470 kΩ bleeder resistors which are contained in the grounding cables of the HCP and VCP are used to prevent the charge applied to the planes from disappearing instantly after the discharge of the ESD generator to the plane. This increases the impact of the ESD event on the EUT. The resistors should be capable of withstanding the maximum discharge voltage applied to the EUT plane during the test. They should be positioned close to each end of the grounding cable to create a distributed resistance

One thought on “ESD Testing (IEC 61000-4-2)”

I agree with your statement about ESD testing being 1 of the first tests to perform on a new product. However, if you are doing an evaluation of a new design, using the full compliance test kit is overkill. You can use a Piezoelectric Torch lighting device like the one in the picture below even at the board stage to provide engineering information to the design team. For that type testing, I have found that the $20 torch lighting device is adequate to assess the prototype or breadboard stage. If the product has a metal container and you need to increase the voltage, add a solid 14 ga insulated wire about 1/2 inch long to the end of the striker. The way to make the wire is to cut an insulated wire, strip enough wire to grab the wire with a pair of pliers. Then twist the insulation and slip it down on the wire about 1/8 of an inch. Slip the insulation over the center wire of the striker until the wire touches the metal wire of the striker. Then bend the center wire back toward the striker until it is close enough to create an arc. Move this around the product while creating arcs and see if the board/design has any faults or stops working. Cheap and easy radiated immunity and ESD testing tool.