Every so often we see online stories of a “fake” phone charger burning down a home or giving people electric shocks. Normally these phone chargers are referred to as ‘Apple’ or ‘iPhone’ chargers, however, that is just because the small triangle chargers (in a variety of colours) are so prevalent.

Chinese Phone Charger

A while ago (pre-Britex referendum) I bought an 89p phone charger (with free shipping) from Ali Express, just to see how ‘good’ it is, let’s just say that you won’t be surprised by any of this:

The Phone charger is a BS1363-ish plug, so testing it is easier than testing either the HLK-PM01 or the cheap Chinese crap one.

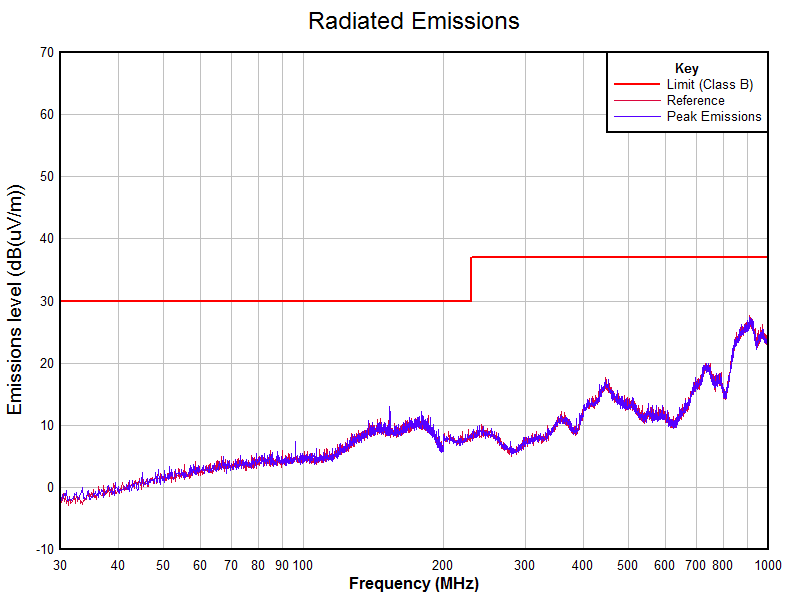

Having a quick go at checking to see how well it conforms to BS EN 55032:2015 – “Electromagnetic compatibility of multimedia equipment. Emission Requirements” (until recently I the beginning of this month I would have considered BS EN 55022 [pdf]), It will have to comply to the Class B (Residential / Domestic) limit lines for conducted and radiated emissions

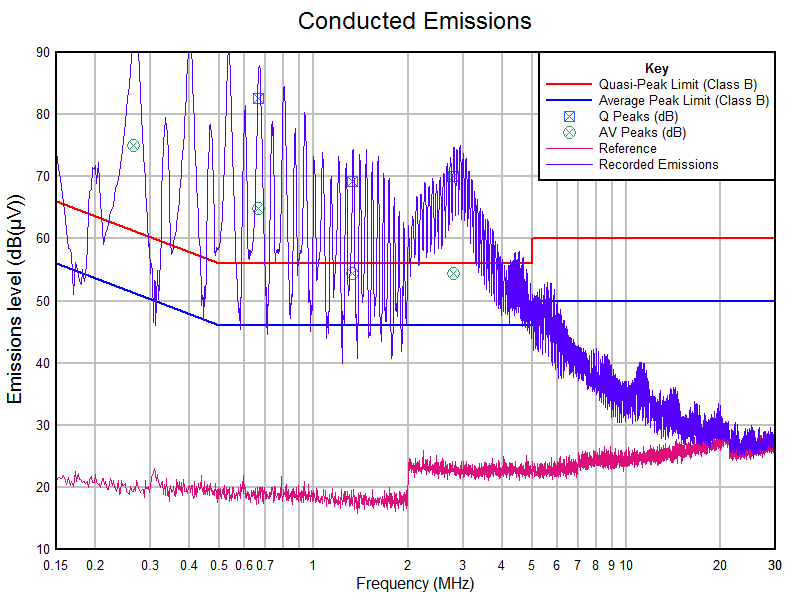

Conducted Emissions

Conducted Emissions testing on the DUT, with class B limits, is performed between 150 kHz and 30 MHz using a LISN. The EMCO 3810/2 LUSN (Line Impedance Stabilization Network) at CASS was used to perform this test.

Conducted Emissions testing gives us these results:

Looking at the conducted emissions graph above (Performed on L1, Neutral was almost identical), you can see it fails to meet the requirements of the conducted emissions test. I have also chosen to put measurement points on to show actual measurements at different frequencies, the Blue square Quasi Peak marks should be below the red line Quasi Peak Class B limit line, whilst the green circular marks showing the Average Peaks should be below the blue average Peak Limit line.

Most of the noise is below the frequency of 6 MHz with it faiding to background by 20 MHz.

The pinkish Reference line is the emissions recorded with the DUT not plugged into the LISN, allowing us to know the ambient noise in the test setup. This reference enables us to be confident that there is no noise being measured from external sources that are not part of the test.

Radiated Emissions

Unlike the Conducted emissions above, there is very few radiated emissions, but this was to be expected based on my knowledge of how Switchmode PSUs, and there was no additional noise on the conducted emissions trace above about 20 MHz.

now we know its not permissible to place the charger on the market in the EU (including the UK) from an emissions point of view. We can now assess its electrical safety.

Phone Charger LVD assessment

While the two above EMC assessments are required to satisfy the requirements for placing the product on the market, they don’t constitute a safety test. The safety requirements compliance comes from performing an LVD (Low Voltage Directive) assessment.

An LVD assessment is destructive since we only have one sample, I have chosen to perform this rather than an ESD test.

Visual Inspection

Looking at the regulatory markings, there is no Class II symbol on regulatory markings, however, all other markings are in position (this predates UKCA).

Functional Testing of the Phone Charger

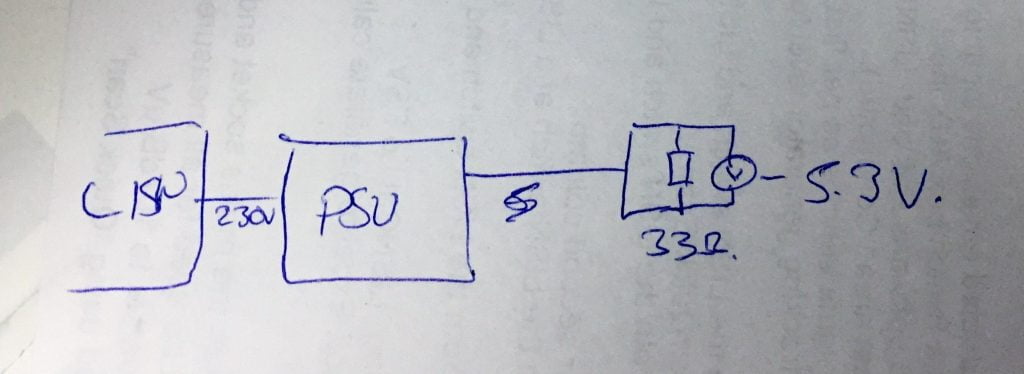

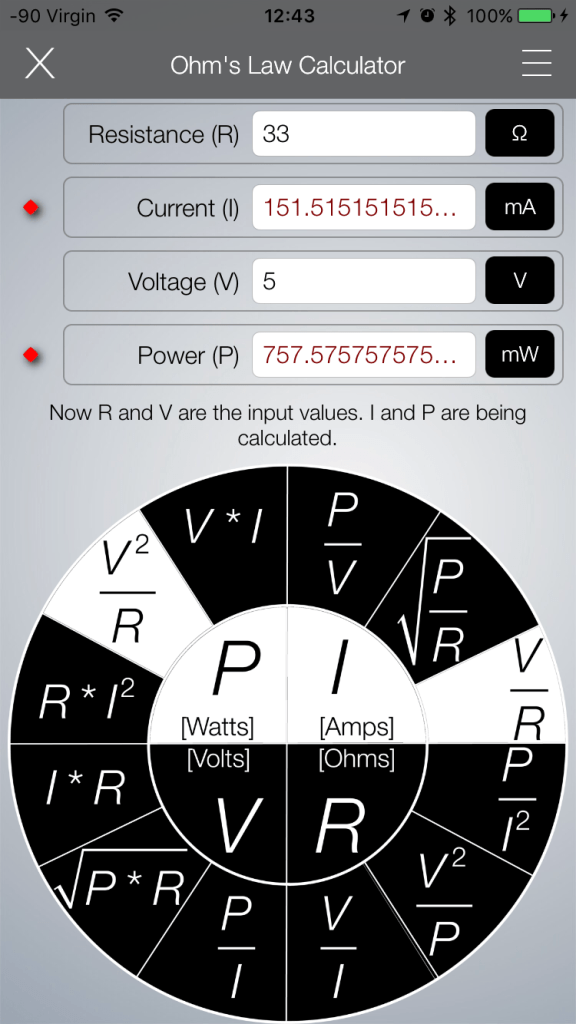

We performed some functional tests, the DUT is attached to a programmable load, and the following measurements were performed.

- Offload DC out 5.3 V

- DC maximum output before supply folded ~1 A

- Power used – 3 W offload, 8 W @ 1 A

After this functional testing breakdown testing was carried out, the breakdown test failed at 600 Vac, with a failure current of 1 mA and did not recover.

Breakdown testing was performed with Live and Neutral pins tied together, and the earth taken via the shield of the USB socket.

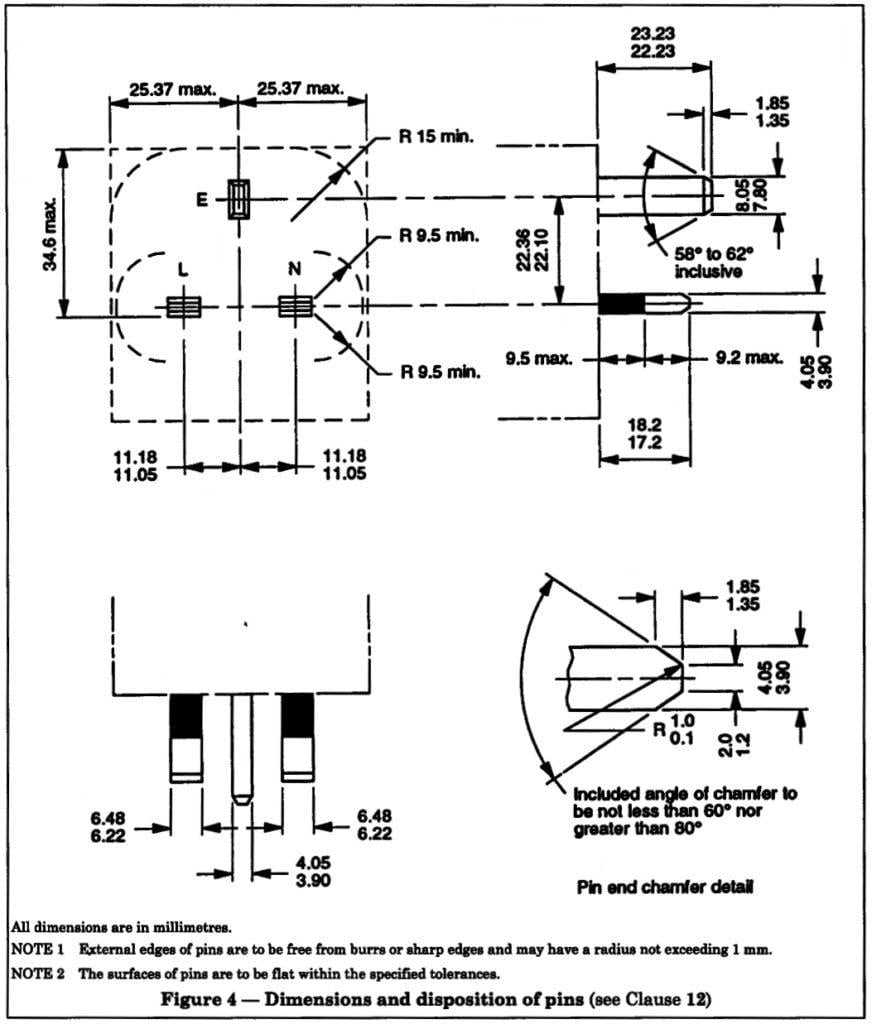

Compliance with Dimensional requirements of BS1363.

Looking at the compliance with the dimensions set out in BS1363:

We performed the test to confirm compliance with the dimensional requirements of BS1363, using a gauging block we found that pins were not dimensionally correct, if there was no deviation the DUT would fit flush with the face of the block. Also given that the side of the plug was almost flush with the side of the block, I took a measurement and it shows as 9.67 mm, the minimum is 9.5 mm.

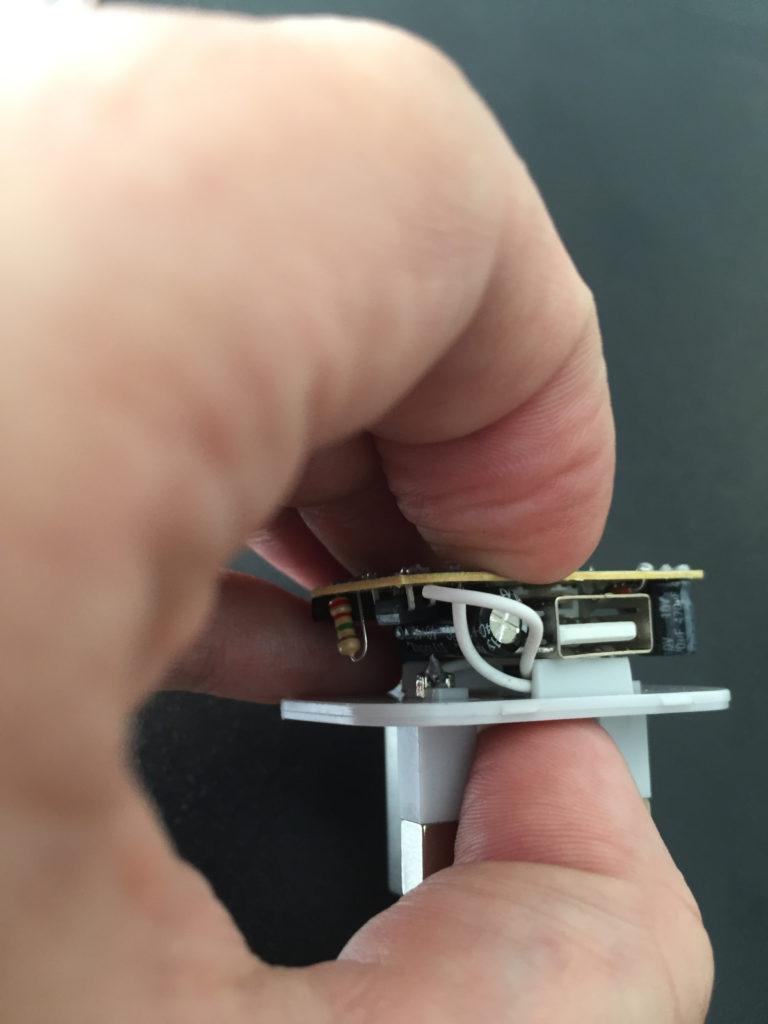

Internal Assessment

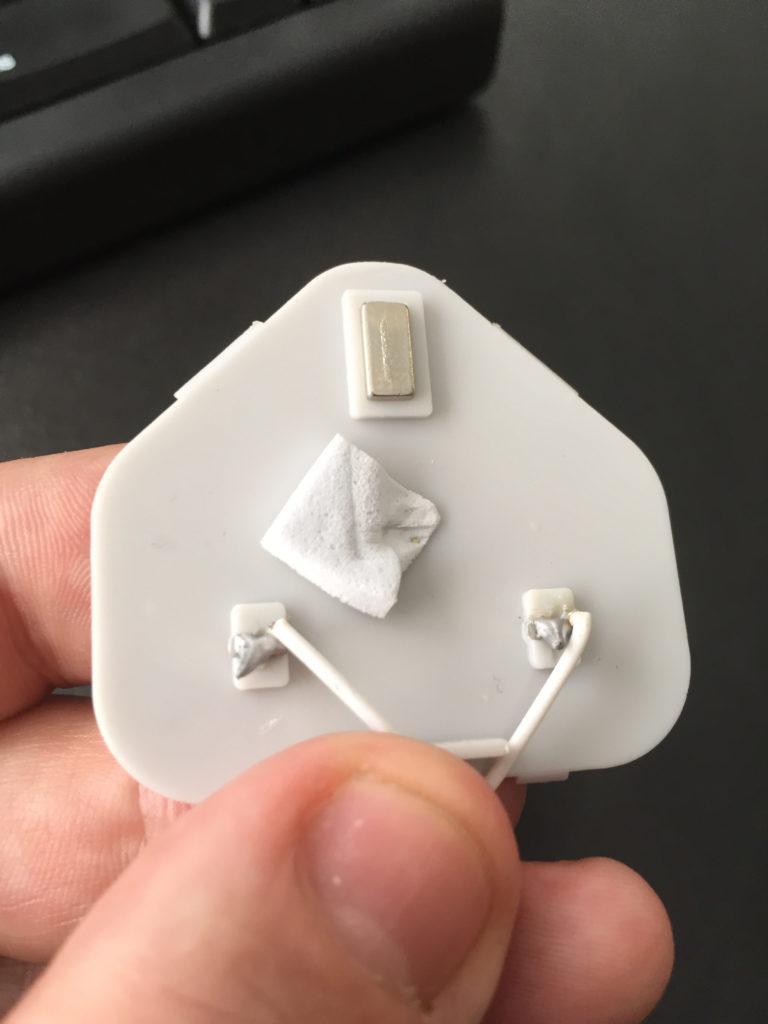

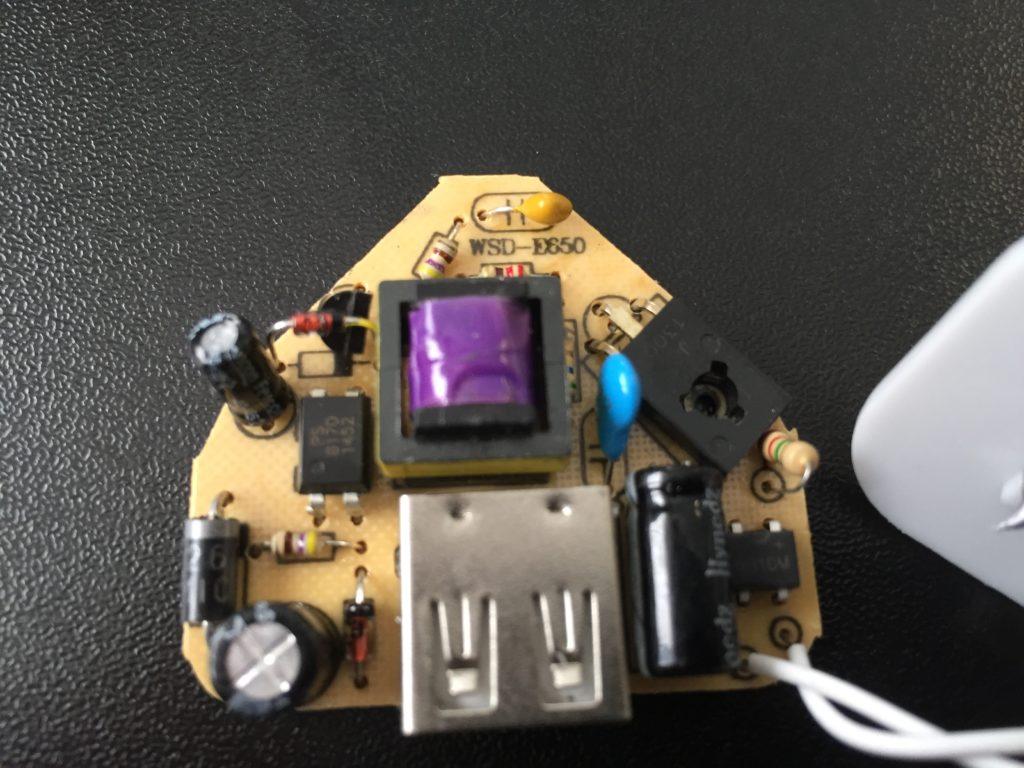

The phone charger was carefully dismantled allowing them to be visually assessed in situ.

There are several significant issues with the layout of this fake iPhone charger, some of which were more significant than others.

Issues with the Phone Charger

The results for the LVD screen test:

- No secondary securing of internal primary wire to pins, or PCB.

- Single insulation mains in contact with LV / Secondary side.

- No physical barrier between Pins and PCB

- The capacitor between the Primary and Secondary circuits is not Y-rated.

- The separation between Primary and Secondary does not meet the requirements.

- No mains fuse fitted

- Solder on the rear of pins in physical contact with the capacitor on the secondary side.

- No Class II symbol on regulatory markings

I am sure it is safe to say that I was not surprised by the lack of conformity of the charger, I was however surprised at just how terrible it was!

One thought on “Autopsy of a Phone Charger from China”

I will buy much crap directly from China but I really don’t have the balls to order stuff that touches 230V.