Since the electronics on my Remote Control ROV will be underwater, they need to be isolated from the water, and the subsequent water pressure, for this I am going to use a pressure vessel.

There is a commercial product the “SEAWOLF Ocean Master” that looks like it has a transparent acrylic pressure vessel.

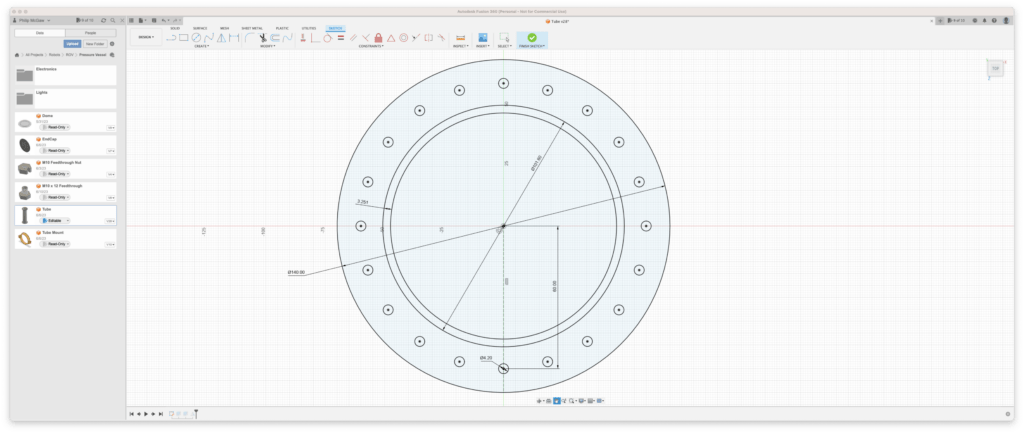

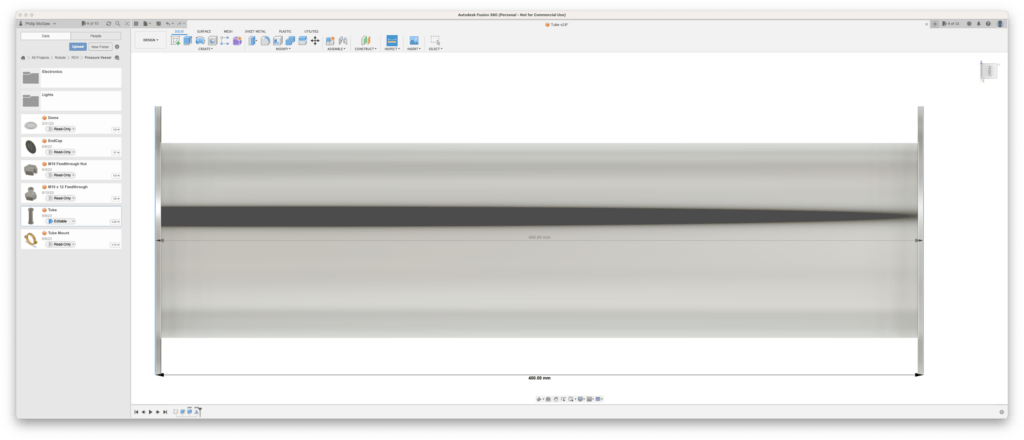

The basic design for my pressure vessel is to be a tube of about 100 mm in diameter, the length of which is determined by the length of the side pieces of my ROV, in this instance it is 400 mm.

The minimum internal diameter is constrained by the space required for the electronics, and all the auxiliary equipment.

The maximum external diameter is constrained firstly by the availability of materials, the frame, and the external pressure.

The greater the external dimensions the thicker the wall needs to be to resist the forces acting on it by the external pressure, also the greater the dimension the larger the end caps need to be, also the longer the tube the thicker the wall needs to be to resist the same pressure

About 100 mm or four inches has been settled on for the diameter because this seems to be a good compromise for material availability and resistance to external forces (and aesthetically it looks right).

The main tube of the ROV Pressure Vessel

| Material | Stainless Steel 304 | Acrylic (cast) | Aluminium 6082-T6 | Steel BS 1387 (mild) | |

|---|---|---|---|---|---|

| Yield Strength | 179 MPa | 55 MPa | 250 MPa | 250 MPa | |

| Working Strength | 5.5 MPa | ||||

| Youngs Modulus | 200 GPa | 2.4 GPa | 71 GPa | 200 GPa | |

| Density | 7.9 gr/cu cm | 1.15 gr/cu cm | 2.71 gr/cu cm | 7.8 gr/cu cm | |

| Poisson’s Ratio | 0.27 | 0.35 | 0.33 | 0.33 | |

| Internal Diameter | ~97 mm | 94 mm | ~ 95 mm | ~ 98 mm | ~ 106 mm |

| External Diameter | 101.6 mm | 100 mm | 101.6 mm | 101.6 mm | 114.3 mm |

| Wall Thickness | 2 mm | 3 mm | 3.26 mm | 1.63 mm | 4.05mm |

| Price (400 mm) ex VAT | £37.20 [link] | £14.34 [link] | £11.03 [link] | £6.52 [link] | £41.01 [link] |

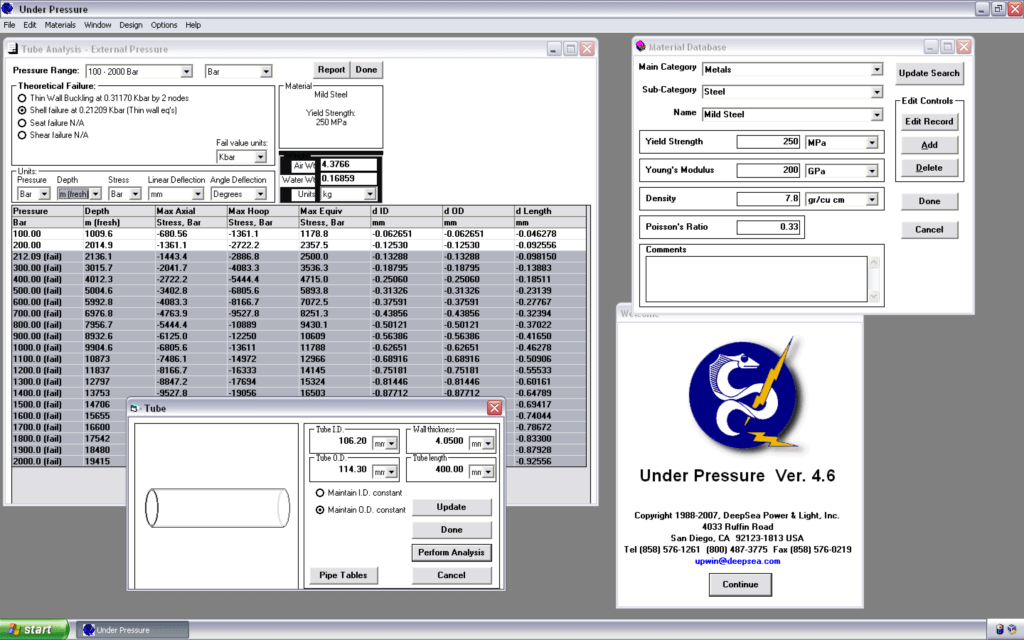

Steel is the easiest material to weld, However, one Issue I have on this is that I have never tried welding… so let’s look at the performance of each tube. Using the above information we can use a Windows application called “Under Pressure” by Deepsea to work out the performance of a tube made from each material.

| Material | Stainless Steel 304 | Acrylic Cast | Aluminium 6082-T6 | Steel BS 1387 (mild) | |

|---|---|---|---|---|---|

| wall thickness | 2 mm | 3 mm | 3.26 mm | 1.63 mm | 4.05 mm |

| Weight in Air | 2.89 kg | 0.422 kg | 1.13 kg | 0.57 kg | 4.38 kg |

| Weight in Water | -0.33 kg | -2.79 kg | -2.2 kg | -2.75 kg | 0.169 kg |

| Failure Mode | Shell Failure | Thin Wall Buckling | Thin Wall Buckling | Thin Wall Buckling | Shell Failure |

| Failure Pressure | 117 Bar | 2.1 Bar | 77.3 Bar | 14 Bar | 212 Bar |

| Failure Depth (Freshwater) | 1184 m | 22.1 m | 781 m | 142 m | 2136 m |

| Failure Depth (Salt Water) | 1165 m | 21.8 m | 768 m | 139 m | 2100 m |

While it is clear from the above two tables that the Steel BS 1387 is more than capable of withstanding any external pressure that could be applied to it, and the price of £41 is more than reasonable, the external diameter is a little larger than I was hoping for.

Cast Acrylic tube is often used by people making ROVs similar to the open ROV, however, the extension of the tube length from 100 mm to 400 mm reduces the failure depth from 91 m to 22 m in fresh water.

The 304 stainless or Aluminum both look to be the best compromise with cost and depth performance, So the assessment comes down to the ease of welding.

In subsequent posts, I will talk about the endcaps and generate data about the pressure for them as well.